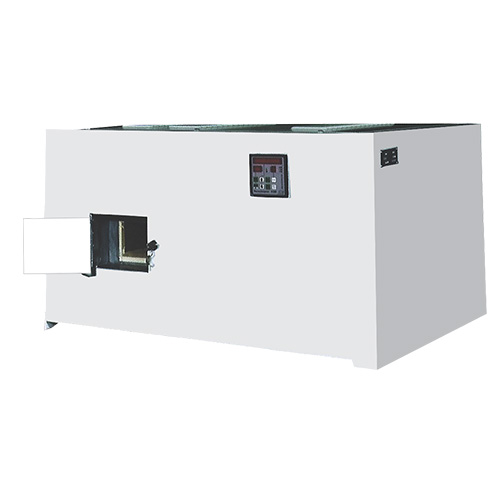

Gradient Kiln Gkmc-1

Standards

The purpose of this gradient kiln is to obtain a series of temperature readings from samples during a single firing cycle. The style of kiln is ideal for trials of ceramic glazes, colours and clay bodies, insulators and sanitaryware etc. In this style of kiln a fixed gradient of approximately 20/25°C would be apparent between each of the nine measuring point.Overall there is an approximate gradient of 180°C across the nine thermocouples between the “hot” and “cold” ends. As standard the kilns incorporate a TCS2 microprocessor controller, able to store 99 programs with up to 99 segments per programme, offering total flexibility in the firing curve.

TECHNICAL SPECIFICATIONS

• Maximum design temperature 1300°C

• Fixed gradient

• 9 samples fired at one time

• 20/25°C between each reference point

• TCS2 Microtech programme controller

• Voltage: 230-50 Hz single phase

| Code | Model | Internal dimensions of the room | Power |

|---|---|---|---|

| GT2013 | KILN GKMC-1 | 65x50x460 mm | 3 kW |

| Code | Description | Image |

|---|---|---|

| GT2057 | Software/Hardware to enable data logging to pc windows with 3mt connection cable | |

| GT2058 | Chart recorder |

Related products

Gradient Kiln Gkm-6

Description:

Gradient kiln equipped with 6 programmable muffles up to 1280 °C

Category:

Firing Gradient KilnsStandard:

Gradient kiln equipped with 6 programmable muffles up to 1280 °C

Gradient Kiln Gks-6

Description:

Gradient kiln equipped with 6 programmable muffles up to 1300°C.

Category:

Firing Gradient KilnsStandard:

Gradient kiln equipped with 6 programmable muffles up to 1300°C.