Electrical Roller kiln

Standards

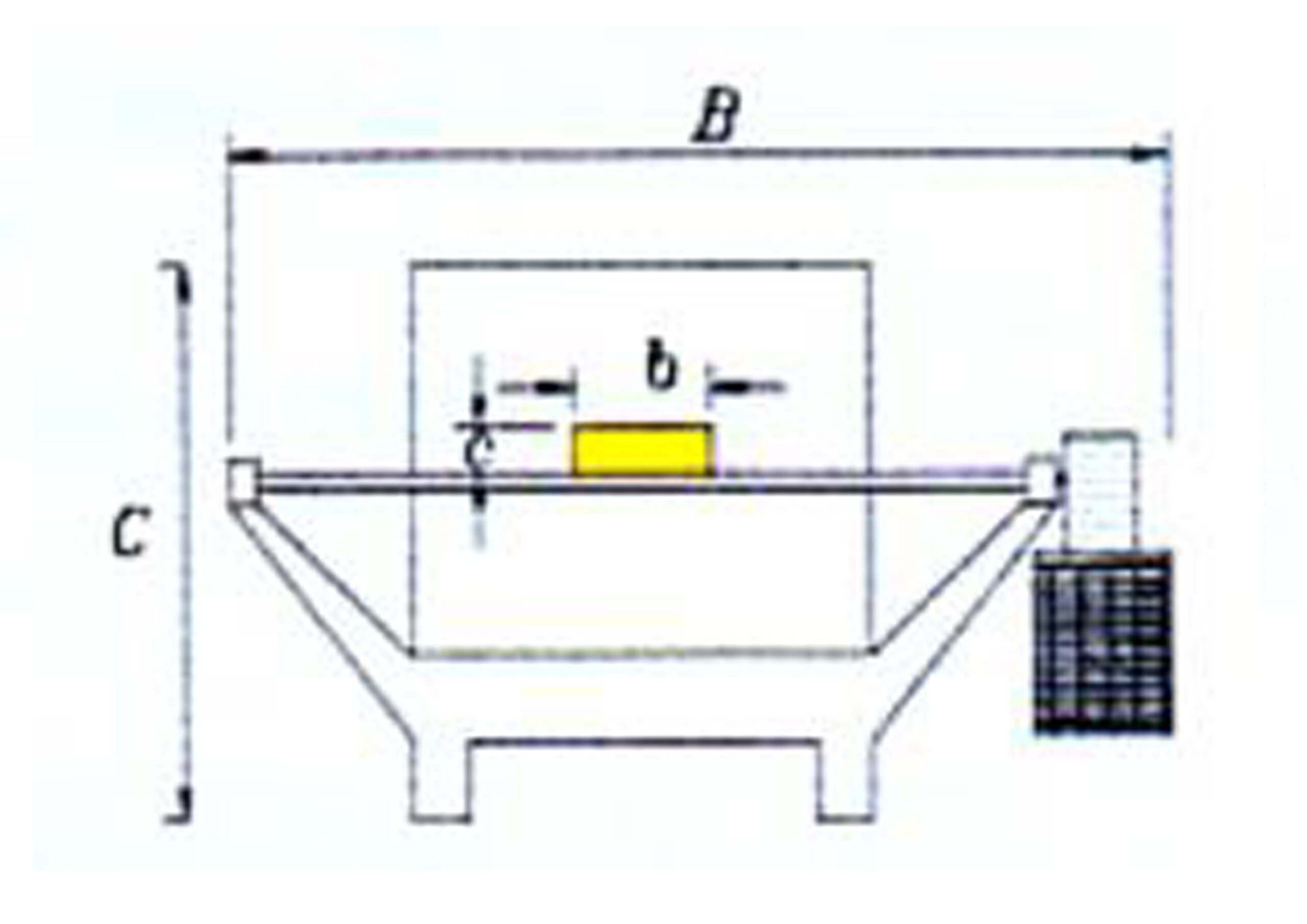

The kiln consists of a sturdy steel structure, which encloses the thermal insulation, consisting of low density refractory bricks and preformed ceramic fibre sheets, highly resistant to high temperature and thermal shock. The kiln has several zones with different characteristics:

– Entrance and smoke evacuation zone

– Preheating zone

– Firing zone

– Cooling zone

TECNICAL SPECIFICATIONS

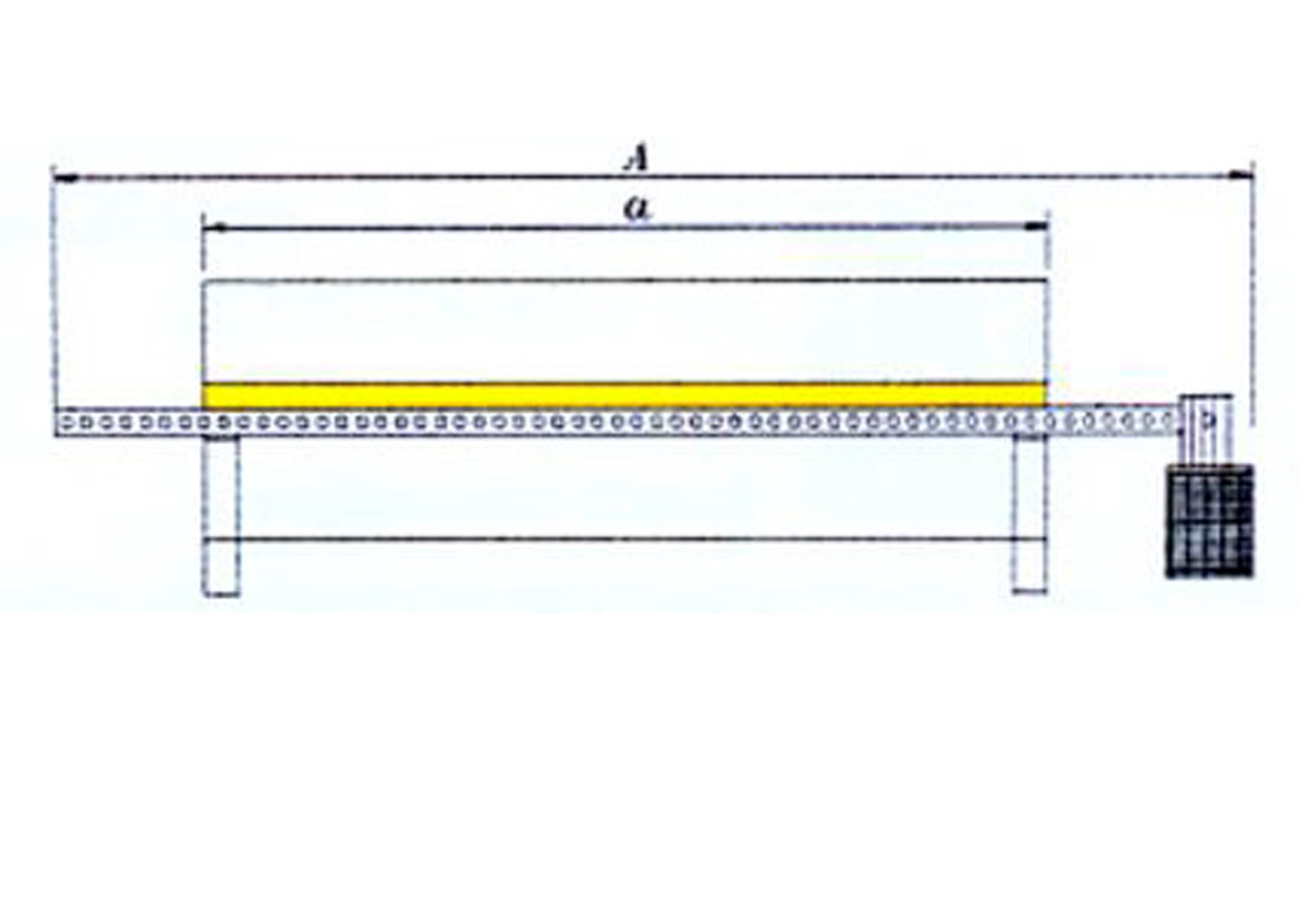

The transport of the tiles in the kiln takes place by means of ceramic rollers, which are rotated by means of a pinion-chain system with variable speed. The drive system makes it possible

to exchange the rollers in a very short time.

COMBUSTION SYSTEM

The combustion system consists of electrical heating elements in Kanthal in spiral form, supported by ceramic tubes and easily exchangeable. The heating elements in the firing zone are made of silicium carbide, enabling these models to work at a max. temperature of 1.330°C. Each zone provided with heating elements (preheating and firing zones) is controlled by a self-regulating potentiometric pyrometer, which controls the static units.

| Code | Model | External dimensions | Power | Temperature | Voltage | Weight | ROLLS Ø |

|---|---|---|---|---|---|---|---|

| GT2470 | KILN LRK 10 | 1670x1000x750 mm | 5 Kw | 1330 °C | 230 V + N | 202 Kg | 20 mm |

| GT2471 | KILN LRK 15 | 2320x1090x1525 mm | 9 Kw | 1330 °C | 400 V + N | 330 Kg | 20 mm |

| GT2472 | KILN LRK 20 | 3400x1100x1550 mm | 16 Kw | 1330 °C | 400 V + N | 548 Kg | 20 mm |

| GT2473 | KILN LRK 25 | 3830x1200x1570 mm | 18 Kw | 1330 °C | 400 V + N | 700 Kg | 20 mm |

| GT2474 | KILN LRK 30 | 4650x1185x1430 mm | 35 Kw | 1330 °C | 400 V + N | 980 Kg | 20 mm |

| GT2326 | KILN LRK 45 | 6085x1185x1540 mm | 35 Kw | 1330 °C | 400 V + N | 1230 Kg | 20 mm |

| Code | Description | Image |

|---|

Related products

Laboratory Roller Kiln LRK-1230 / 140-1220

Description:

Laboratory roller kiln permits simulation of any firing cycle, faithfully reproduing the required operating conditions.

Category:

Firing Roller KilnsStandard:

Laboratory roller kiln permits simulation of any firing cycle, faithfully reproduing the required operating conditions.